Fast, accurate measurement of punched inner layers improves overall registration accuracy!

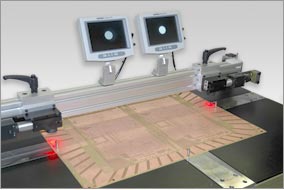

The importance of quick and accurate measurement of inner layers has led Multiline Technology to develop the Verifier VER 1000. This unique measuring machine is designed to check inner layers after post-etch punching for repeatability and to determine if offsets are necessary for the punch. Although this can be accomplished using coordinate measuring machines, they can be costly and cumbersome and often not accessible to the inner layer production people for quick verifi cations. The VERIFIER is a precision gauge with vision repeatable to better than 0.00004” (1ìm) and panel positioning accuracy within a 0.0002” (5ìm) envelope.

The VERIFIER offers real time inspection of etched targets on a post

etched punched inner layer in comparison to the theoretical centerline position, thereby

confi rming the “split-the-difference” capability of the system, as well as the accuracy of target placement

on the inner layers. The ease of operation and set up, which does not require special routines or programs,

insures that inspection can be done outside of QC.

The VERIFIER offers real time inspection of etched targets on a post

etched punched inner layer in comparison to the theoretical centerline position, thereby

confi rming the “split-the-difference” capability of the system, as well as the accuracy of target placement

on the inner layers. The ease of operation and set up, which does not require special routines or programs,

insures that inspection can be done outside of QC.

The value of a Verifier is to confirm that panels being processed on the Optiline PE or ATP post etch punch are in tolerance. While Multiline Post Etch punches are exceptionally accurate, inspection of the product coming off of them is essential to monitor machine wear, establish maintenance schedules or to compare the results of multiple machines. The Verifier (VER 1000) can be used to establish offsets which can be entered into the Post Etch Punches to actually improve registration accuracy. When production requires multiple machines it is used to calibrate each punch to a single standard, reducing even the slightest variation present in tolerances from utilizing more than one machine.

The value of a Verifier is to confirm that panels being processed on the Optiline PE or ATP post etch punch are in tolerance. While Multiline Post Etch punches are exceptionally accurate, inspection of the product coming off of them is essential to monitor machine wear, establish maintenance schedules or to compare the results of multiple machines. The Verifier (VER 1000) can be used to establish offsets which can be entered into the Post Etch Punches to actually improve registration accuracy. When production requires multiple machines it is used to calibrate each punch to a single standard, reducing even the slightest variation present in tolerances from utilizing more than one machine.

The Verifier is used to calculate the offset values based on a sampling of panels.The Verifier emulates pin lamination registration by using specially designed tapered pins with fl ats similar to but having a shorter bearing surface than the lamination pins used in the actual lay up of the panel. The tapered pin insures that the panel is pinned without variation and that it will accommodate variations in slot widths due to material types and thickness ranges.

To receive more information on the Verifier VER 1000 through e-mail contact Multiline Technology or fill out our Literature Request Form.